Product Video

Machine’s Tech. Parameters

| Machine Power | 500W |

| Power Supply | AC220V/50 – 60HZ (default and variable if needed) |

| Labeling Speed | 0-200 bottles per minute min (depending on the size of the bottle, label length) |

| Accuracy | ±1.0mm |

| Machine Size(L*W*H) | 1800*700*1400mm |

| Machine Net Weight | 150.00kg |

| Bottle Outer Diameter Range | Ф10-25mm |

| Label Length Range | 15-75mm |

| Label Roller max. Outer Diameter | Ф300mm |

| Label Roll min. Inner Diameter | Ф76mm |

| Single Label Spacing | ≥3mm |

| Label thickness | ≥8um, |

| the thickness of backing paper | ≥5um, and allowing for a certain degree of tensile strength reserved |

How to use this labeling machine

- Label Loading

First to remove the upper label plate, loosen the lower pallet fixing screws, adjust to the height of the labeling desired, tighten the fixing screws; put the roll of labels on the label plate with the label plate tightening ring pressure, load the upper label plate, in the state of the material tray slack, pull out the label, according to the route indicated in the schematic diagrams, wear a good roll of labeling tape, the head is fixed with a clip to the receiving tray, adjusting the roller tightly rolled height to the height of the position of the sticker

2 Adjusting the products feeding structure device

3 Adjusting the parallelism of the stripping portal

It aims to make the stripping plate parallel to the labeling mechanism and the conveyor belt surface, so that the label can be correctly applied in parallel during labeling.

4 Adjusting the printing position

According to the imagining printing position on the label, loosen the bottom plate bolts to adjust the front and rear printing position, tighten the bolts (if the position is not enough, you can also adjust the angle iron position), the high and low position can be adjusted to the position of the coder mounting bracket.

5 Adjusting the photoelectric sensors-Won’t you please check out the photo-electricity manual book.Thank you.

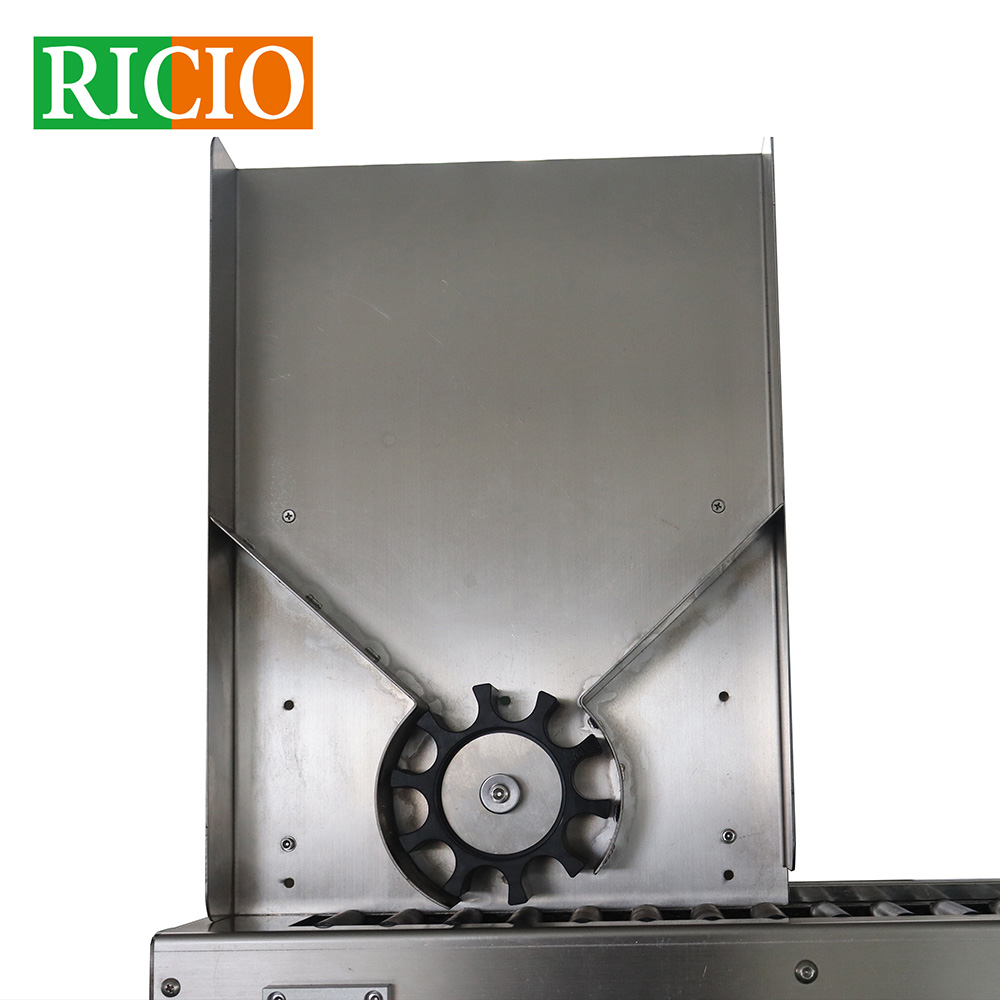

6 Adjusting the roller and label pressure mechanisms

Depending on the size and height of bottle, the height of the label roller mechanism can be adjusted (the same diameter of the labeling tape and the bottle is appropriate) and the label pressure mechanism.

7. Before starting this labeling machine, check whether the material, the host head, the labeling mechanism and other related parts correspond to the bottle, open the touch screen and press the “labeling test” switch, observe whether the labeling is still in place, put a few bottles on the conveyor belt to be labeled and press the “run start” switch to observe whether the actions are coordinated; whether the photoelectric signal output; whether the labeling requirements are met. Observe whether the actions are coordinated; whether the photoelectric signal output; whether it can meet the labeling requirements. If everything is normal, mass production can be carried out, in the whole process of trying, such as the emergence of unforeseen circumstances, the operator can press the emergency stop switch.