Product Video

Tech. Parameters

| Voltage | AC220V 50/60HZ |

| Power | 2000W |

| Capacity | 60~150b/m(Adjustable speed, depending on object size and label length) |

| Accuracy | ±1mm(depends on object&label sizes and labeling pattern) |

| Bottle Diameter | 25-120mm |

| Bottle Height | H40mm~400mm(Can be customized) |

| Label Size | H10mm~150mm L10~300mm(Can be customized) |

| Size of Paper Roll | Inner diameter of label roll:Ф76mm;outer diameter of label roll:Ф300mm |

| single label spacing | ≥3mm |

| label thickness | ≥8um, the thickness of the backing paper is≥5um, and have a certain tensile strength |

| Weight | 280kg |

| Dimension | 2800*1400*1600mm |

| Conveyor Width | Can be customized according to the diameter of the sample bottle |

Machine Performances

Double Side Sticker Labeling Machine can automatically stick the label to the designated position of the bottle; at the same time, it can print the batch number, production date and output count. In the absence of bottles, the control system to ensure that the label is not sent to effectively prevent the waste of labels, and according to the production characteristics of each factory labeling speed for stepless speed regulation, so as to ensure that the machine can be used individually or in line with other machines to use the labeling components to make the surface of the bottle is not too flat to get a satisfactory labeling effect. It can be adapted to various specifications, colors, materials of round bottles, so this type of labeling machine is so widely used in medicine & pharmaceuticals, food & beverage, light industry, daily chemicals and other industries.

Machine Operations Workflow

Step 1: Manually put the labeled products (line or bottle carousel)

Step 2: Products are automatically separated and corrected and conveyed

Step 3: Product inspection

Step 4: Product labeling

Step 5: To collect the labeled products (into the next process)

Final Step: To take away the finished labeled products.

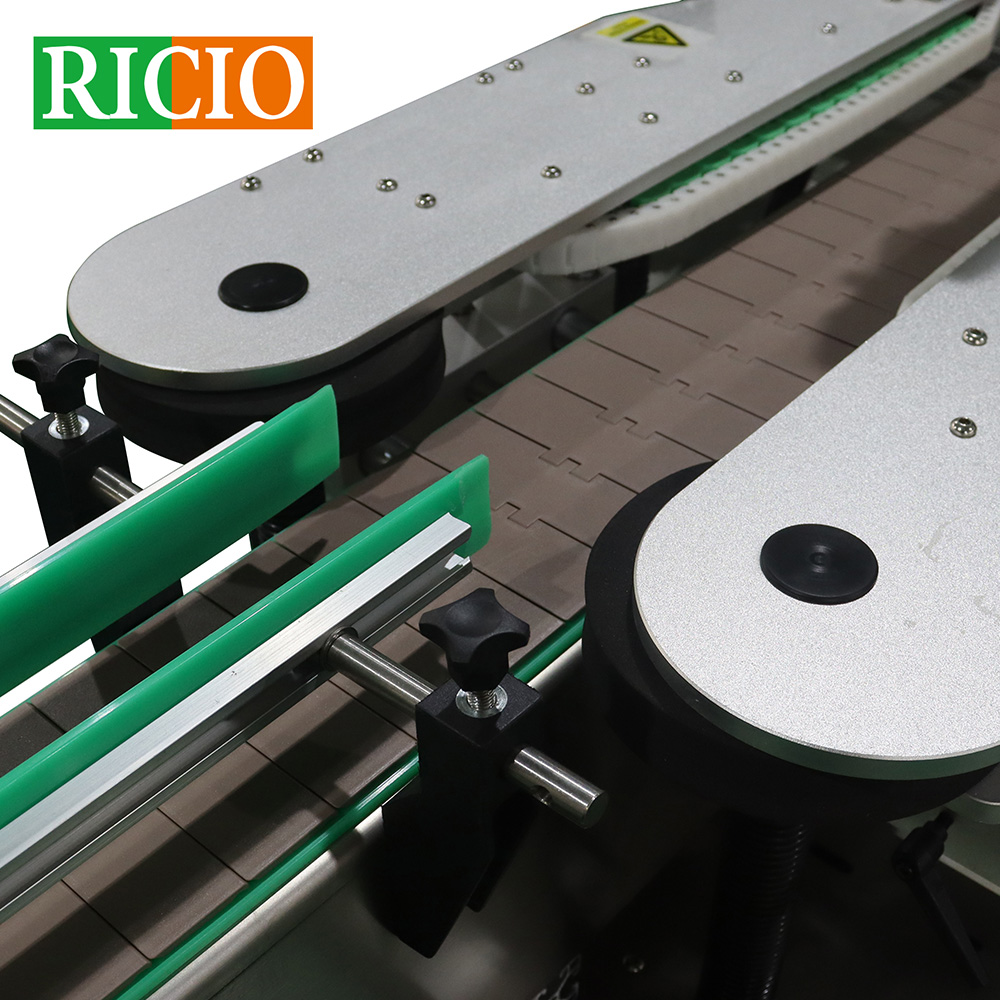

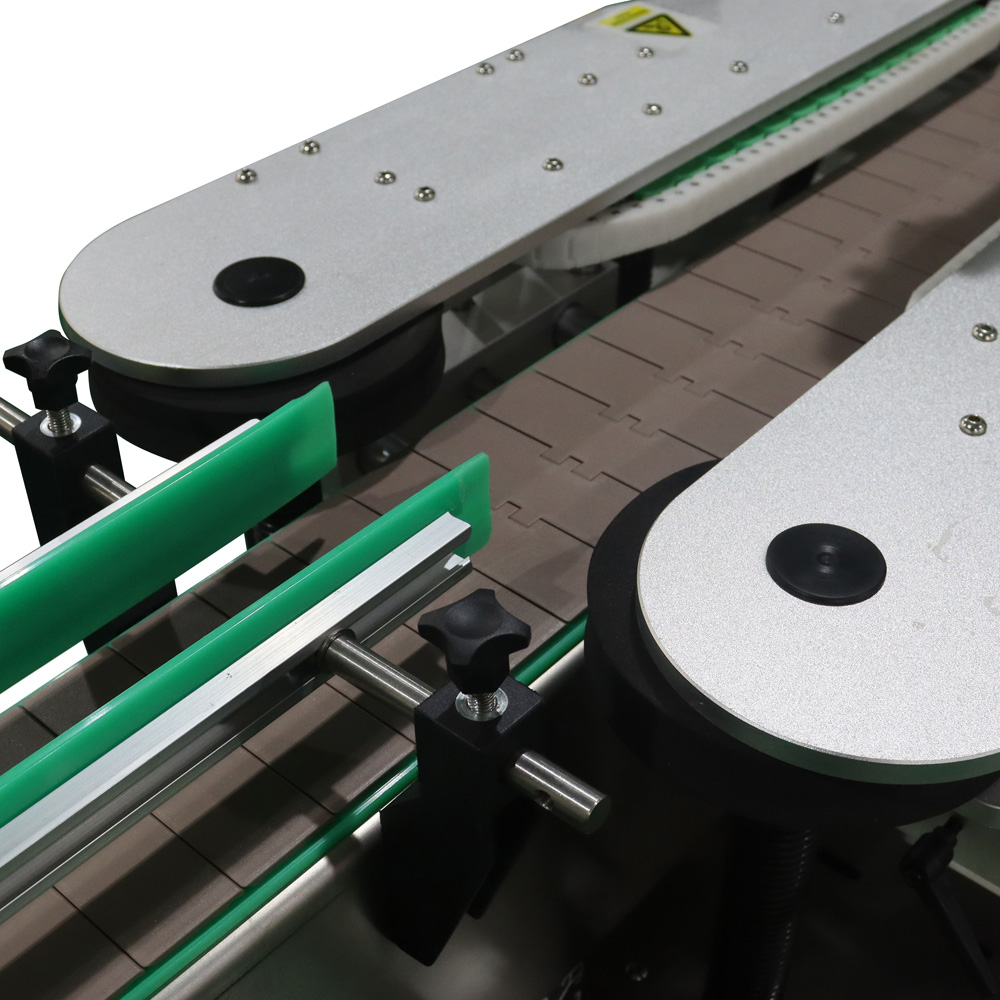

The bottle separating and correcting mechanism:

Precise differential speed bottle separating machine .The accuracy of separating bottles is up to ±5mm. Bottles of different sizes, no need to replace the parts, cost-saving and easy to adjust and easy to adjust according to actual status.

The top labeling mechanism:

Motor control, speed in line with the transmission track, control the labeled bottles to keep upright and prevent from falling bottles.

The label collection mechanism:

Motor control and conveyor belt, pull label mechanism synchronization, collect label backing paper.

The label roller mechanism:

Nice look, dust-proof, very easy to change labels.

Machine Work Principle

Different packaging objects will be put into the labeling machine conveyor belt, driven by the conveyor belt bottles into the bottle separation area, then through the calibration device, through the pressure holding mechanism to bring bottle into the labeling area. After entering the labeling area, the optical fiber detects bottles, and transmits the photoelectric signal to PLC, and the output signal is transmitted to the stepping motor after processing by PLC, and the stepping motor outputs the label, and the label is attached to the labeled object by the rolling mechanism, and the labeled object is brought into the next process or container by the labeling machine conveyor belt.

The Advantages & Features of Front And Back Automatic Labeling Machine

- Strong compatibility: The same equipment can realize the single and double-sided and adjacent right-angle surface labeling of many types of products (such as: flat bottles, round bottles, square bottles, shaped bottles, etc.), can be equipped with a round bottle positioning mechanism, round bottle rolling mechanism, 3-side labeling mechanism;

- Flexible application, simple operation: Can be single machine production, can also be connected to the assembly line production; the use of double-sided rigid plastic synchronous guiding chain, automatically ensure the alignment of bottles, greatly reducing the difficulty of workers or assembly line docking; config. of the automatic bottle separator, in the product into the guide mechanism before the automatic separation of the spacing, to ensure that the subsequent bottle guide, conveyor and labeling stability;

- Equipped with double labeling mechanism: The first labeling to ensure labeling accuracy, the second extrusion labeling, effectively eliminate air bubbles and ensure that the labeling head and tail at the tight;

- Adopting new type of elastic pressure top mechanism: To ensure smooth product delivery and effectively eliminate the bottle height error itself;

- Sticking to the standard is accurate: High stability, the use of PLC+ subdivision stepper motor drive to send label, send the standard is accurate; cam-type brake mechanism, the tension is uniform, to ensure that the label band taut, reduce the label pull off, to ensure that the label detection is accurate; label band around the corrective mechanism to prevent the label from shifting left and right, to ensure that the accuracy of labeling.

- With powerful, color touch screen control panel: Both Chinese & English languages free-shift optional human interface (HMI), convenient and intuitive, powerful data memory function, can store 50 groups of labeling parameters, with production counting function, power-saving function, production number setting prompt function, parameters setting protection function, convenient production management, different products labeling switch a key to achieve, no need to repeatedly debugging, simple and fast; and has a perfect fault prompts/debugging and help functions and has a perfect fault prompts and help functions;

- High stability performance: Executing high measuring standards, measuring sensors using imported first-rate brands, high detection sensitivity, stable performance and durability; stable and durable machine base and various components, are adopted standardized modular design with full interchangeability, 24-hour operation, to ensure safety and stability.

- Safety and hygiene of machine operations & maintenance: The machine chassis is made of high quality materials with stainless steel SUS304 and T6 aluminum alloy, never rust, in line with GMP excellent manufacturing standards;

Machine Components Config. List

| Machine Component Name | Qty | Unit | Brand | Origin |

| HIM | 1 | Unit | SIEMENS/TAIDA | Germany |

| PLC | 1 | Unit | SIEMENS/TAIDA | Germany |

| Labeling Rotor | 2 | Unit | PANASONIC | Japan |

| Labeling Rotor Driver | 2 | Unit | PANASONIC | Japan |

| Conveying Rotor | 1 | Unit | ABBA | China |

| Conveying Rotor Frequency Converted | 1 | Unit | SIEMENS | Germany |

| Bottle Separation Rotor | 1 | Unit | JSCC | Germany |

| Bottle Separation Controller | 1 | Unit | JSCC | Germany |

| Calibration Rotor | 1 | Unit | JSCC | Germany |

| Calibration Rotor Controller | 1 | Unit | JSCC | Germany |

| Low Voltage Appliance | 1 | Set | SCHNEIDER | France |

| Labeling Sensor | 2 | Set | OMRON | Japan |

| Labeling Sensor | 2 | Set | OMRON | Japan |

| Synchronous Toothed Belt | 1 | Set | BANDO | Japan |

| Pneumatic Components | 1 | Set | AirTAC | Taiwan |

| Conveying Belt | 1 | Set | LL | China |

| Machine Stand | 1 | Set | SUS304 | China |

| Overall Systems Integration | 1 | Set | RICIO | China |

Application

Optional Config. & Auxiliary Equipment

- Coding machine: Thermal coding machine prints production date, expiration date, production batch number and so on. Coding and labeling synchronization, improve production efficiency.

- Spraying coding machine: Can support the market mainstream coding machine, in the labeling of the specified position for coding, and labeling machine perfect combination.

- Omni-sensor: Those ordinary sensors can not detect transparent labels, it’s wise to choose the German imported Lloyd’s special electric eye supporting the use of sensors.

- Label reader: Can read 2D QR code, bar code and other information to facilitate the establishment of product database for product traceability.