Product Vedio

Waistband Flat-Surface Labeling Machine Tech. Parameters

| Power Supply | (Default) AC220V/50–60HZ (adjustable according to different countries spec. requirements upon proper power supply) |

| Machine Power | 2500W |

| Labeling Speed | 20–60 pcs per minute (flux variable labeling speed performance depending on box size, label size and other factors such as box feeding speed, etc ) |

| Machine Size (L*W *H) | 2.00m*0.85m*1.75m |

| Machine Net Weight | 270.00kg |

| Box Size Range | |

| Length | 120–300 (mm) |

| Width | 50–300 (mm) |

| Height | 20–80 mm |

| Label Length Range | 20–500 (mm) |

| Outer Label Roller Diameter (max) | Φ300 (mm) |

| Inner Label Roller Diameter (min.) | Φ76 (mm) (in some western EU countries, 40mm spec. small label roller width is also seen & adopted so widely) |

| Interval Between Each Label | ≥3mm |

| Label thickness | >8μm, backing paper thickness >5μm, and in consideration of sufficient tensile strength. |

Machine Workflow

(1) Manually put the labeled products (bottle carousel or connecting line)

(2) products are automatically separated and conveyed

(3) products are detected -> products are labeled

(4) labeled products are collected

(5) products are taken away

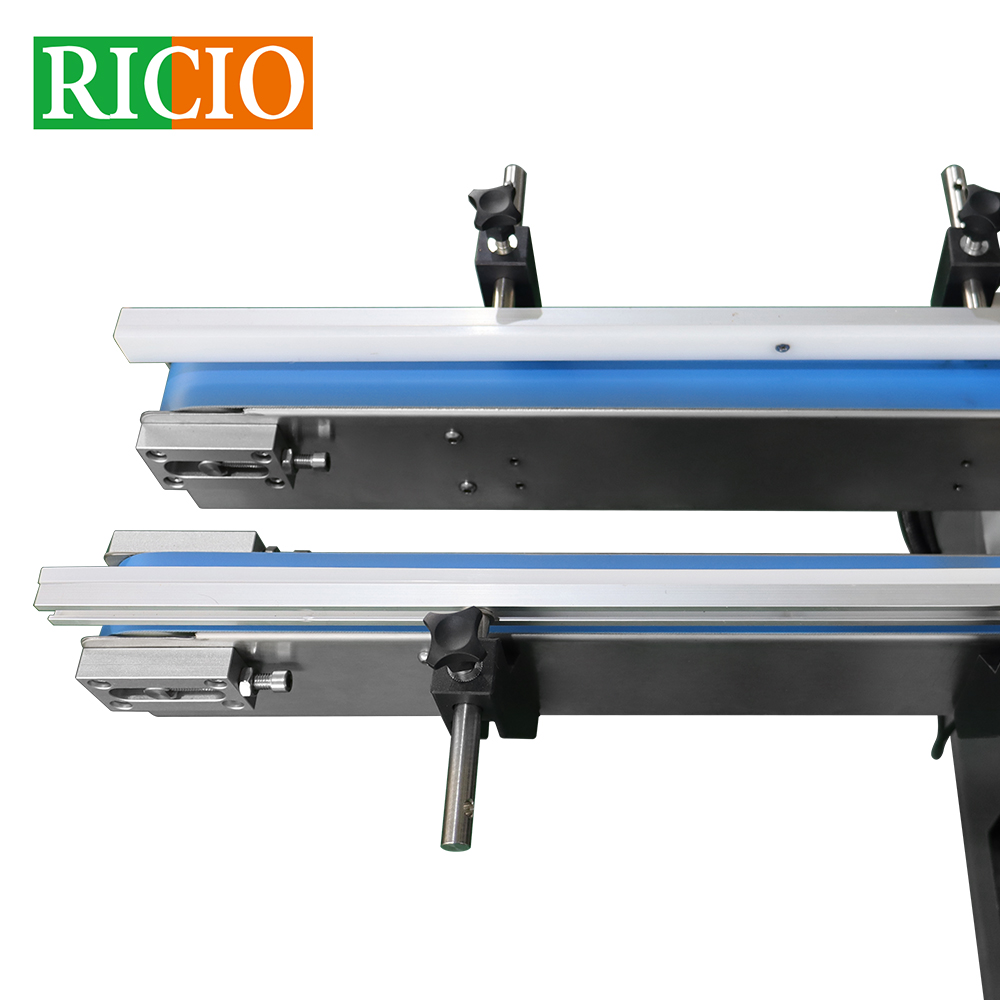

Machine Principle

Objects to be labeled with the conveyor belt into the labeling area, photoelectric detection of it, triggering the labeling machine out of the label, the label is firmly affixed to the product box, and then through the roller labeling wheel will be smoothed label; labeled products and then out with the conveyor belt, into the next process.

Advantages & Features & Benefits

- The whole electronic control system is controlled by PLC, Chinese touch screen operation, easy to operate, intuitive, containing a wealth of help functions and fault display function.

- The most critical component of the labeling machine is the label feeder, we liken the label feeder to the heart of the labeling machine, our label feeder selects the Japanese Tamagawa stepping motor drive to ensure higher precision and better stability.

- The role of the label feeder is to pull the label, so that the label out of the label, affixed to the labeled object, and the key actuator to achieve this action is the drive roller. Our labeling machine using wear-resistant materials made of drive roller, its friction is very good, to ensure that the label movement process does not slip; another feature is very wear-resistant, to overcome the rubber or metal type is easy to be abraded by the phenomenon of label slippage and run off.

- The driving roller with the pressure roller with automatic adjustment of the parallel function, can ensure that the pressure roller and driving roller parallel, and tightly affixed together, there will be no labeling phenomenon of running diagonal.

- The machine’s working status and faults, have a reminder warning function, system operation, shutdown and faults occur, the system will be the occurrence of the event and the end (fault lifting) are recorded and stored, so that the operation and maintenance is more convenient.

- With label management and product counting function, it can realize the counting of the usage and remaining amount of labels, which is convenient for the management of labels, and the counting of products, and it can also flexibly set the counting and management function according to the requirements of customers.

Machine’s Main Parts List

| Parts Name | Qty | Unit | Brand | Origin |

| HIM | 1 | pcs | DELTA | Taiwan |

| PLC | 1 | pcs | DELTA | Taiwan |

| labeling motor | 1 | pcs | Leadshin | China |

| labeling motor driver | 1 | pcs | Leadshin | China |

| conveyor motor | 1 | pcs | SOBG | China |

| conveyor motor frequency converter | 1 | pcs | DELTA | Taiwan |

| corner motor | 1 | pcs | Leadshin | China |

| corner motor driver | 1 | pcs | Leadshin | China |

| low voltage appliance | 1 | set | CHNT | China |

| label sensor | 1 | set | LEUZE | Germany |

| labeling sensor | 1 | set | OMRON | Japan |

| synchronous toothed belt | 1 | set | BANDO | Japan |

| pneumatic components | 1 | set | AirTac | China |

| conveyor | 1 | set | LL Chain | China |

| machine stand | 1 | set | SUS304 | China |

| system integration | 1 | set | RICIO | China |

Optional Accessories

(1) Coding machine: Thermal coding machine prints production date, expiration date, production batch number and so on. Coding and labeling synchronization, improve production efficiency.

(2) Coding machine: can support the market mainstream coding machine, in the labeling of the specified position for coding, and labeling machine perfect combination.

(3) Universal sensor: ordinary sensors can not detect transparent labels, must choose the German imports of Lloyd’s special electric eye supporting the use of.

(4)) Reader: read two-dimensional code, bar code and other information to facilitate the establishment of product database for product traceability.