Round Bottle Labeling Machine VIDEO

Round Bottle Labeler Performances:

Round bottle label applicator can automatically stick the label to the designated position of the bottle; when encountering a lack of bottles, the control system ensures that the label is not sent, effectively preventing the waste of labels, and can be according to the production characteristics of each factory to make stepless speed regulation of the labeling speed, so as to ensure that the machine can be used individually or in line with other machines, the labeling components can make the surface is not quite flat bottle to get satisfied with the labeling effect.

This type round labeling machine can be adapted to a variety of specifications, colors, materials, round bottles, so it is widely used in pharmaceuticals, food & beverage, light industry, daily chemicals and other industries.

This round bottle sticker labeling machine can automatically stick the label to the designated position of the bottle; when encountering a lack of bottles, the control system ensures that the label is not sent, effectively preventing the waste of labels, and can be according to the production characteristics of each factory to make stepless speed regulation of the labeling speed, so as to ensure that the machine can be used individually or in line with other machines, the labeling components can make the surface is not quite flat bottle to get satisfied with the labeling effect.

This type round bottle labeling machine can be adapted to a variety of specifications, colors, materials, round bottles, so it is widely used in pharmaceuticals, food & beverage, light industry, daily chemicals and other industries.

Automatic Round Bottle Labeling machine Tech. Parameters

| Voltage | AC220V 50/60HZ |

| Power | 1000W |

| Capacity | 30~50b/m(Adjustable speed, depending on object size and label length) |

| Accuracy | ±1mm(Depends on object&label sizes and labeling pattern) |

| Bottle Height | H100mm~400mm(Can be customized) |

| Bottle Diameter | Φ30~130mm(Large diameter span requires replacement of bottle clamping mold) |

| Label Size | H20mm~150mm L15~300mm(Can be customized) |

| Size of Paper Roll | Inner diameter of label roll:Ф76mm;outer diameter of label roll:Ф300mm |

| Weight | 200kg |

| Dimension | 2000*1300*1500mm |

Round Bottle Label Applicator FAB (Feature & Advantages & Benefits)

Clamp positioning self-adhesive type labeling machine RXL-DW can automatically stick the label to the designated positioning of the bottle; in case of lack of bottles, the control system ensures that the label will not be sent to effectively prevent the waste of labels, and according to the production characteristics of each factory to make stepless speed regulation of the labeling speed to ensure that the machine can be used individually or inline with other machines, the labeling components can make the surface not too flat bottle to get the satisfaction of the labeling effect.

Round Bottle Sticker Labeling Machine Workflow

-> Manually put the labeled products (line or bottle carousel)

-> Products are automatically separated and corrected and conveyed

-> Products are inspected

-> Products are labeled

-> Labeled products are collected (going to the next process)

-> Products are taken away.

Round Labeling Machine Work Principle

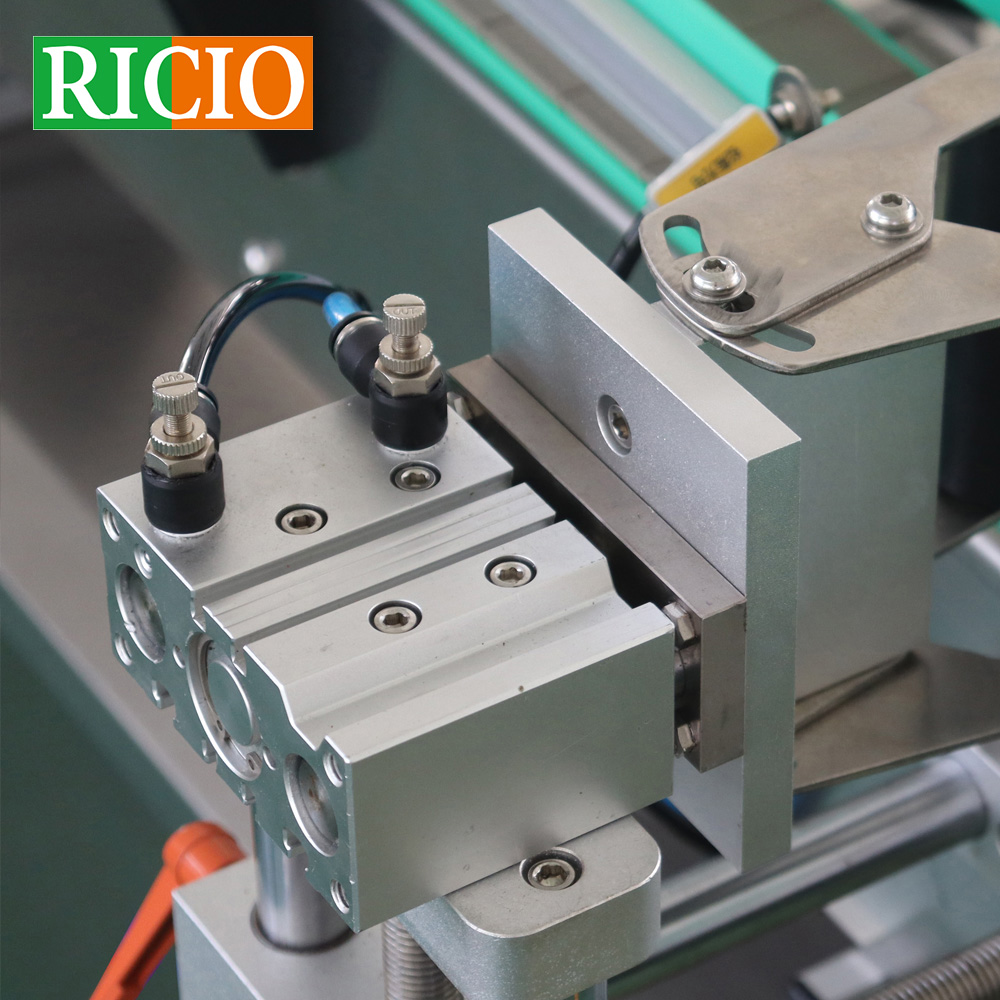

Bottle from the conveyor belt into the card bottle station (for reciprocating movement), roll labeling wheel driven bottle rotation in place, at this time the detection of photoelectric detection of bottles and give a signal to the PLC, PLC to pull the labeling stepper motor to send out the action instructions; labels from the peeling mouth peeled out of the stick to the bottle, the bottle with the label in the rotation, the entire label on the bottle; in the stop label photoelectric detection of the label gap to give the PLC a signal; PLC Pull the labeling stepper motor to send a stop command to complete the first labeling, the second labeling start command is through the detection of the roll labeling wheel stepper motor in the completion of the first labeling rotating angle size to determine the starting positioning. Labeling action is the same as above; in the completion of the surface of the two labeling, the card bottle release, will complete the labeling of the bottle sent out to bring in the next bottle to the labeling area.

Round Label Applicator Standard Config. Components List

| The Model RXL-DW Pneumatic Clamp Orientation Self-Adhesive Type Label Application Machine | ||||

| Components Name | Qty | Unit | Brand Name | Origin |

| HIM | 1 | set | SIEMENS | Germany |

| PLC | 1 | set | SIEMENS | Germany |

| Labeling Servo Motor | 1 | pcs | Leadshine | Joint-venture |

| Labeling Motor Driver | 1 | pcs | Leadshine | Joint-venture |

| Conveyor Motor | 1 | pcs | MAILI | China |

| Bottle Separator Motor | 1 | pcs | Leadshine | China |

| Label Roller Motor | 1 | pcs | Leadshine | China |

| Label Roller Motor Driver | 1 | pcs | Leadshine | China |

| Low Voltage Appliance | 1 | set | SCHNEIDER | France |

| Label Senso | 1 | set | LEUZE | Japan |

| Labeling Sensor | 1 | set | KEYENCE | Japan |

| or | ||||

| OMORON | ||||

| Synchronized Tooth Belt | 1 | set | BANDO | Japan |

| Pneumatic Components | 1 | set | AirTAC | Taiwan |

| Conveyor | 1 | set | Shanghai LL | China |

Round Bottle Labeler Optional Accessories

(1)Coding Printer: thermal coding machine prints production date, expiration date, production batch number and so on. Coding and labeling synchronization, improve production efficiency.

(2)Spraying Printer: can support the market mainstream coding machine, in the labeling of the specified positioning for coding, and labeling machine perfect combination.

(3)Omni-Sensor: ordinary sensors can not detect transparent labels, must choose the German imported well-known brand – LEUZE special electric eye supporting the use of labeling machine.

(4)Supporting Data Reader: can read 2D QR code, barcode and other information to facilitate the establishment of product database for product traceability.