| Product Paramenters | |

| Voltage Specifications | AC220V 50/60HZ (according to user) |

| Power Consumption | 1200W |

| Labeling Speed | 30~60 tubes/min(adjustable speed, according to the size of object and label length) |

| Percentage of labeling | ±1.0mm (according to products characteristics, hardness and roundness) |

| Air Pressure | 0.4~0.6Mpa |

| Object Range | According to product spec. To make mold |

| Label Specifications | Φ6~25mm (can be customized if needed) |

| Inner Diameter of Paper Roll | |

| roll diameter inner | Φ76mm |

| roll diameter outer | Φ300 |

| Weight | 200KG |

| Package Size | 2000*1000*1500mm |

| The above tech. Parameters are based on the standard machine, we can offer customization service if needed. | |

Structure features:

- Fixed-point labeling standards are accurate, small error.

- Reduce bottle friction damage, to ensure the integrity of the appearance.

| Components List | ||||

| Parts Name | Qty | Unit | Brand | Origin |

| HIM | 1 | pcs | SIEMENS | Germany |

| PLC | 1 | pcs | SIEMENS | Germany |

| Labeling servo motor | 1 | pcs | OMRON | Japan |

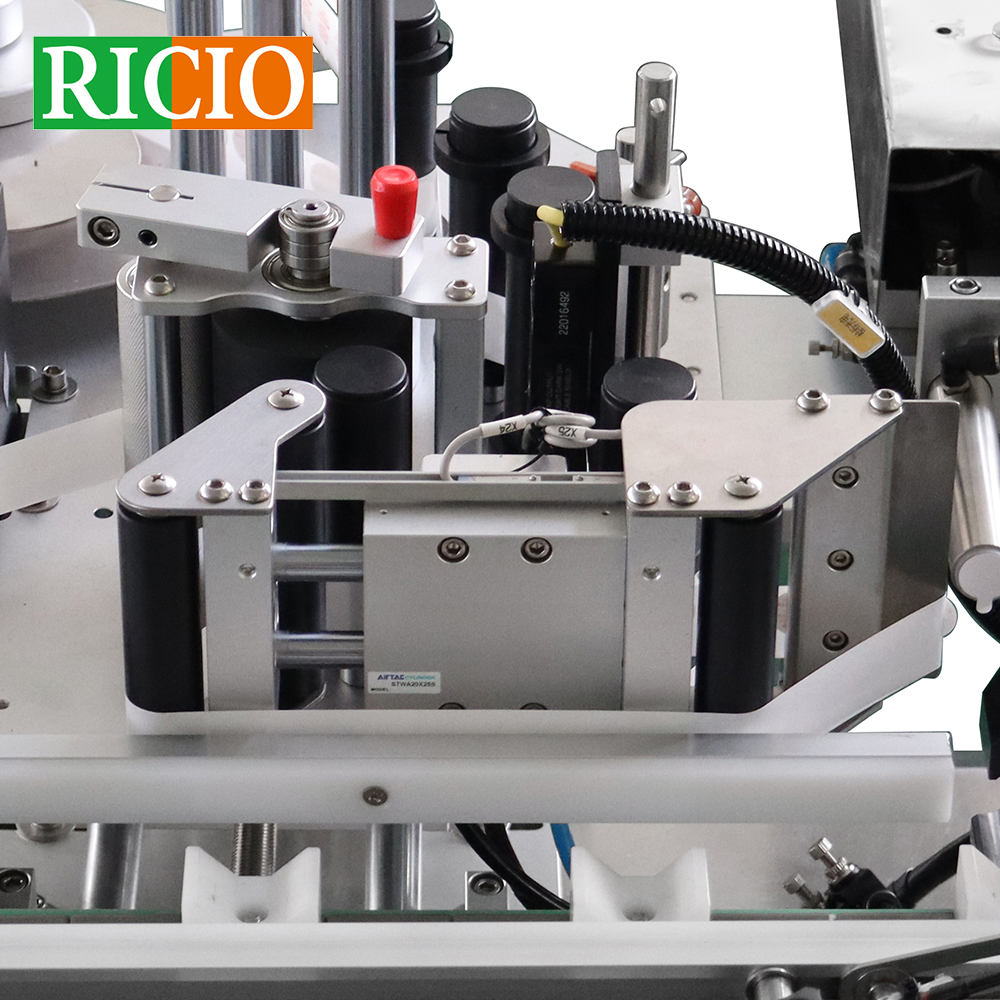

| Solenoid valve | 2 | set | AirTAC | Taiwan |

| Labeling cylinder | 1 | pcs | AirTAC | Taiwan |

| Conveyor motor | 1 | pcs | OMRON | Japan |

| Conveyor motor frequency converter | 1 | pcs | OMRON | Japan |

| Low voltage appliance | 1 | set | SCHNEIDER | France |

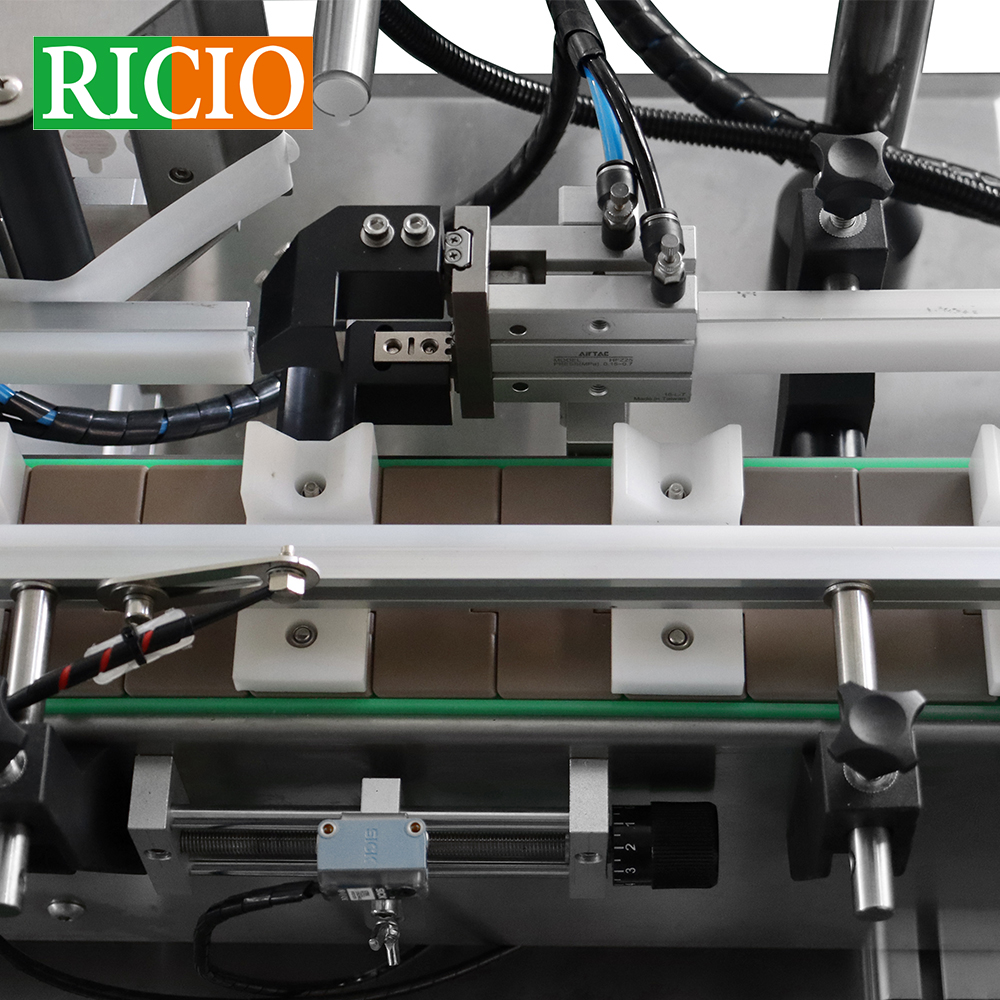

| Label sensor | 1 | set | OMRON | Japan |

| Labeling sensor | 1 | set | OMRON | Japan |

| Synchronous toothed belt | 1 | set | BANDO | Japan |

| Pneumatic components | 1 | set | AirTAC | Japan |

| Conveyor | 1 | set | LL | China |

| Machine stand | 1 | set | SUS304 | China |

| System integration | 1 | set | RICIO | China |

Work flow:

- Place the product in the special mold, conveyor driven product movement.

- Arrive at the designated workstation, photoelectric detection of the product. Labeling machine out of the label.

- Labeling end, push the labeling mechanism to withdraw, the product falls into the mold, conveyor movement, take away the product.